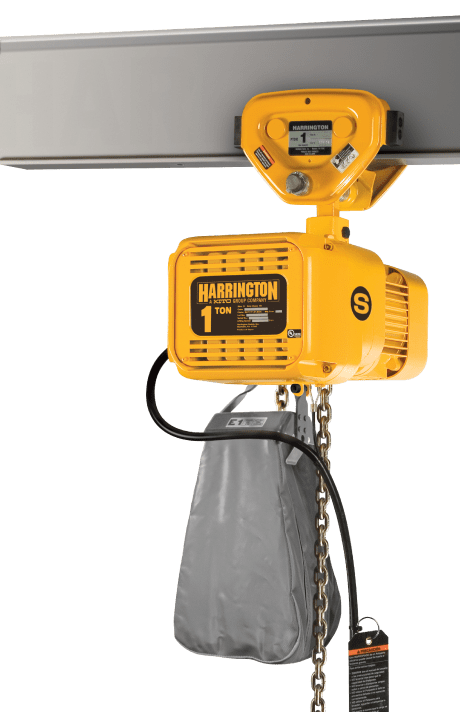

ELECTRIC CHAIN HOISTS

Engineered to Endure

Our NER/ER electric hoists are designed for peak performance—even on the toughest jobs in the toughest conditions. Quiet operation and minimal vibration lowers workplace noise pollution, helps reduce worker fatigue and extends the life of the hoist.

CAPACITY

- ⅛ – 5 Ton

VOLTAGE

- 208-230/460-3-60

- Dual speed models are not reconnectable

COMPLIANCE

- UL 1340 – Most models shipped with UL listing. Contact Customer Service for listed models.

- ANSI/NFPA 70, “National Electrical Code”

- ANSI/ASME B30.16, “Safety Standard—Overhead Hoists (Underhung)”

- ANSI/ASME HST—1M, “Performance Standard for Electric Chain Hoists”

CLASSIFICATION

- ASME H4

- ISO M5 or M4

- FEM 2m or 1Am

BODY

- Rated IP55

- Die-cast aluminum

- Completely sealed body for for both indoor and outdoor applications, including harsh environments

- Low headroom

- Easy access external pins allow for quick change from hook to lug for trolley mount configurations on most models

GEARS

- Heat treated helical and spur gears are precision machined for long life

- Oil bath lubrication promotes a quiet, smooth, cool operation

LOAD CHAIN

- Ultra-strong high-performance and corrosion resistant nickel-plated

- Grade 80 DIN chain

- Made with unique technology to greatly increase resistance to fatigue and wear

OPERATION

- Pendant control

- Under-the-cover VFD standard for dual speed hoists. Speed ratio is 6:1 with adjustability up to 12:1

- Plug in pendant and power supply cords save time on set up and maintenance

HOOKS

- Forged carbon steel

- Open gradually without fracturing under excessive loads

- Bottom hook swivels 360 degrees

- Top and bottom hooks have heavy-duty hook latch

GREEN INITIATIVE

- Built smarter without the use of harmful materials

- Environmentally friendly

- RoHS compliant

PUSH BUTTON PENDANT

- Rated IP65

- Standard control voltage is 110V

- Strain relief wire is molded to pendant cord for added support and dependability

- Single speed: 2-button (momentary contacts)

- Dual speed: 2-button (momentary contacts) with emergency On/Off (maintained contacts)

- E-stop is standard on all 2-button dual speed pendants

BRAKE

- “The Guardian”: Smart Brake Technology

- Revolutionary DC current motor brake with electrical failsafe design

- 10 year warranty

MOTOR

- Totally enclosed fan-cooled (TEFC)

- Motor fin, fan blade and fan cover design cools the motor and brake

OPERATING CONDITIONS

- Recommended for -4° to +104° F and humidity of 85% or less

OPTIONS

- Plastic, canvas, or steel chain containers

- Longer lift or pendant lengths

- Other voltages

- Smart Limit

NERM/ERM ELECTRIC TROLLEY HOIST – 3 PHASE

One Smooth Operator

Add a MR motorized trolley to your Harrington NER/ER electric hoist to increase productivity and decrease unwanted movement so you can easily direct your load. Opt for an adjustable two-speed unit with a variable frequency drive (VFD) and you’ll also be able to set your speed preference and ensure super smooth starts and stops every time.

CAPACITY

- ⅛ – 5 Ton

VOLTAGE

- 208-230/460-3-60

- Dual speed models are not reconnectable

COMPLIANCE

- UL 1340 – Most models shipped with UL listing. Contact Customer Service for listed models.

- ANSI/NFPA 70, “National Electrical Code”

- ANSI/ASME B30.16, “Safety Standard—Overhead Hoists (Underhung)”

- ANSI/ASME HST—1M, “Performance Standard for Electric Chain Hoists”

CLASSIFICATION

- ASME H4

- ISO M5 or M4

- FEM 2m or 1Am

BODY

- Rated IP55

- Die-cast aluminum

- Completely sealed body for for both indoor and outdoor applications, including harsh environments

- Low headroom

- Easy access external pins allow for quick change from hook to lug for trolley mount configurations on most models

GEARS

- Heat treated helical and spur gears are precision machined for long life

- Oil bath lubrication promotes a quiet, smooth, cool operation

LOAD CHAIN

- Ultra-strong high-performance and corrosion resistant nickel-plated chain

- Grade 80 DIN chain

- Made with unique technology to greatly increase resistance to fatigue and wear

OPERATION

- Pendant control

- Under-the-cover VFD standard for dual speed hoists. Hoist speed ratio is 6:1 with adjustability up to 12:1. Trolley speed ratio is 6:1 with adjustability up to 10:1.

- Plug in pendant and power supply cords save time on set up and maintenance

HOOKS

- Forged carbon steel

- Open gradually without fracturing under excessive loads

- Bottom hook swivels 360 degrees

- Top and bottom hooks have heavy-duty hook latch

GREEN INITIATIVE

- Built smarter without the use of harmful materials

- Environmentally friendly

- RoHS compliant

PUSH BUTTON PENDANT

- Rated IP65

- Standard control voltage is 110V

- Strain relief wire is molded to pendant cord for added support and dependability

- 4-button (momentary contacts) with emergency on/off (maintained contacts)

- E-stop is standard on all 4-button pendants

BRAKE

- “The Guardian”: Smart Brake Technology

- Revolutionary DC current motor brake with electrical failsafe design

- 10 year warranty

MOTOR

- Totally enclosed fan-cooled (TEFC)

- Motor fin, fan blade and fan cover design cools the motor and brake

OPERATING CONDITIONS

- Recommended for -4° to +104° F and humidity of 85% or less

TROLLEY FEATURES

- Drop Stops

- Bumpers

- Shafts fit wide flange range and have spacers for easy adjustments

- All steel wheels have sealed ball bearings and will fit a flat or tapered beam flange

OPTIONS

- Plastic, canvas, or steel chain containers

- Longer lift or pendant lengths

- Longer shafts for wider beams

- Other voltages

NERP/ERP ELECTRIC TROLLEY HOIST – 3 PHASE

Rock Solid Dependability

Mounting our NER/ER Series hoists to a PT push trolley will create an easy and economical method of transporting the load. This combination is ideal for small workshops and infrequent moves.

CAPACITY

- ⅛ – 5 Ton

VOLTAGE

- 208-230/460-3-60

- Dual speed models are not reconnectable

COMPLIANCE

- UL 1340 – Most models shipped with UL listing. Contact Customer Service for listed models.

- ANSI/NFPA 70, “National Electrical Code”

- ANSI/ASME B30.16, “Safety Standard—Overhead Hoists (Underhung)”

- ANSI/ASME HST—1M, “Performance Standard for Electric Chain Hoists”

CLASSIFICATION

- ASME H4

- ISO M5 or M4

- FEM 2m or 1Am

BODY

- Rated IP55

- Die-cast aluminum

- Completely sealed body for for both indoor and outdoor applications, including harsh environments

- Low headroom

- Easy access external pins allow for quick change from hook to lug for trolley mount configurations on most models

GEARS

- Heat treated helical and spur gears are precision machined for long life

- Oil bath lubrication promotes a quiet, smooth, cool operation

LOAD CHAIN

- Ultra-strong high-performance and corrosion resistant nickel-plated

- Grade 80 DIN chain

- Made with unique technology to greatly increase resistance to fatigue and wear

OPERATION

- Pendant control

- Under-the-cover VFD standard for dual speed hoists. Speed ratio is 6:1 with adjustability up to 12:1

- Plug in pendant and power supply cords save time on set up and maintenance

HOOKS

- Forged carbon steel

- Open gradually without fracturing under excessive loads

- Bottom hook swivels 360 degrees

- Top and bottom hooks have heavy-duty hook latch

GREEN INITIATIVE

- Built smarter without the use of harmful materials.

- Environmentally friendly

- RoHS compliant

PUSH BUTTON PENDANT

- Rated IP65

- Standard control voltage is 110V

- Strain relief wire is molded to pendant cord for added support and dependability

- Single speed: 2-button (momentary contacts)

- Dual speed: 2-button (momentary contacts) with emergency On/Off (maintained contacts)

- E-stop is standard on all 2-button dual speed pendants

BRAKE

- “The Guardian”: Smart Brake Technology

- Revolutionary DC current motor brake with electrical failsafe design

- 10 year warranty

MOTOR

- Totally enclosed fan-cooled (TEFC)

- Motor fin, fan blade and fan cover design cools the motor and brake

OPERATING CONDITIONS

- Recommended for -4° to +104° F and humidity of 85% or less

TROLLEY FEATURES

- Drop Stops

- Shafts fit wide flange range and have spacers for easy adjustments

- All steel wheels have sealed ball bearings and will fit a flat or tapered beam flange

OPTIONS

- Plastic, canvas, or steel chain containers

- Longer shafts for wider beams

- Bumpers

- Longer lift or pendant lengths

- Other voltages

NERG/ERG ELECTRIC TROLLEY HOIST – 3 PHASE

Delivering Results & Reliability

Mounting our NER/ER Series hoists to a GT geared trolley will create an easy and economical method of transporting the load. This combination is ideal for small workshops and infrequent moves.

CAPACITY

- ⅛ – 5 Ton

COMPLIANCE

- UL 1340 – Most models shipped with UL listing. Contact Customer Service for listed models.

- ANSI/NFPA 70, “National Electrical Code”

- ANSI/ASME B30.16, “Safety Standard—Overhead Hoists (Underhung)”

- ANSI/ASME HST—1M, “Performance Standard for Electric Chain Hoists”

CLASSIFICATION

- ASME H4

- ISO M5 or M4

- FEM 2m or 1Am

BODY

- Rated IP55

- Die-cast aluminum

- Completely sealed body for for both indoor and outdoor applications, including harsh environments

- Low headroom

- Easy access external pins allow for quick change from hook to lug for trolley mount configurations on most models

GEARS

- Heat treated helical and spur gears are precision machined for long life

- Oil bath lubrication promotes a quiet, smooth, cool operation

LOAD CHAIN

- Ultra-strong high-performance and corrosion resistant nickel-plated

- Grade 80 DIN chain

- Made with unique technology to greatly increase resistance to fatigue and wear

OPERATION

- Pendant control

- Under-the-cover VFD standard for dual speed hoists. Speed ratio is 6:1 with adjustability up to 12:1

- Plug in pendant and power supply cords save time on set up and maintenance

HOOKS

- Forged carbon steel

- Open gradually without fracturing under excessive loads

- Bottom hook swivels 360 degrees

- Top and bottom hooks have heavy-duty hook latch

GREEN INITIATIVE

- Built smarter without the use of harmful materials.

- Environmentally friendly

- RoHS compliant

PUSH BUTTON PENDANT

- Rated IP65

- Standard control voltage is 110V

- Strain relief wire is molded to pendant cord for added support and dependability

- Single speed: 2-button (momentary contacts)

- Dual speed: 2-button (momentary contacts) with emergency On/Off (maintained contacts)

- E-stop is standard on all 2-button dual speed pendants

BRAKE

- “The Guardian”: Smart Brake Technology

- Revolutionary DC current motor brake with electrical failsafe design

- 10 year warranty

MOTOR

- Totally enclosed fan-cooled (TEFC)

- Motor fin, fan blade and fan cover design cools the motor and brake

OPERATING CONDITIONS

- Recommended for -4° to +104° F and humidity of 85% or less

TROLLEY FEATURES

- Drop Stops

- Shafts fit wide flange range and have spacers for easy adjustments

- All steel wheels have sealed ball bearings and will fit a flat or tapered beam flange

OPTIONS

- Plastic, canvas, or steel chain containers

- Longer shafts for wider beams

- Bumpers

- Longer lift or pendant lengths

NER/ER CYLINDER CONTROL ELECTRIC HOIST

Single-Handed Operation

Available in single or dual speeds these user-friendly hoists have a 60 minute duty rating, H4 classification, thermal motor protection, extreme duty motor and “The Guardian” Smart Brake Technology. Providing ergonomic comfort to users, these are the perfect hoists for high repetitive assembly operations.

CAPACITY

- 1/8 – 1/4 Ton

VOLTAGE

- 208-230/460-3-60

- Dual speed models are not reconnectable

STANDARDS

- ANSI/NFPA 70, “National Electrical Code”

- ANSI/ASME B30.16, “Safety Standard—Overhead Hoists (Underhung)”

- ANSI/ASME HST—1M, “Performance Standard for Electric Chain Hoists”

CLASSIFICATION

- ASME H4

- ISO M5

- FEM 2m or 1Am

BODY

- Rated IP55

- Die-cast aluminum

- Completely sealed body for for both indoor and outdoor applications, including harsh environments

- Low headroom

- Easy access external pins allow for quick change from hook to lug for trolley mount configurations on most models

GEARS

- Heat treated helical and spur gears are precision machined for long life

- Oil bath lubrication promotes a quiet, smooth, cool operation

LOAD CHAIN

- Ultra-strong high-performance and corrosion resistant nickel-plated

- Grade 80 DIN chain

- Made with unique technology to greatly increase resistance to fatigue and wear

OPERATION

- Cylinder control

- Under-the-cover VFD standard for dual speed hoists. Speed ratio is 6:1 with adjustability up to 12:1

- Plug in power supply cord save time on set up and maintenance

HOOKS

- Forged carbon steel

- Open gradually without fracturing under excessive loads

- Bottom hook swivels 360 degrees

- Top and bottom hooks have heavy-duty hook latch

GREEN INITIATIVE

- Built smarter without the use of harmful materials.

- Environmentally friendly

- RoHS compliant

CYLINDER CONTROL

- Standard control voltage is 110V

- In-line handgrip permits one handed operation

- Available on the hoist or as a kit for field installation

BRAKE

- “The Guardian”: Smart Brake Technology

- Revolutionary DC current motor brake with electrical failsafe design

- 10 year warranty

MOTOR

- Totally enclosed fan-cooled (TEFC)

- Motor fin, fan blade and fan cover design cools the motor and brake

OPERATING CONDITIONS

- Recommended for -4° to +104° F and humidity of 85% or less

CHAIN CONTAINER

- Plastic

OPTIONS

- Longer power supply length

- Other voltages

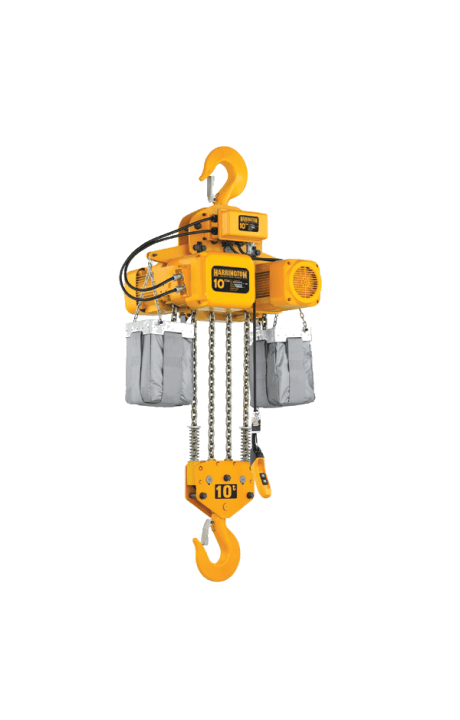

NER/ER LARGE CAPACITY ELECTRIC HOIST – 3 PHASE

It’s What’s Inside that Counts

Harrington’s NER/ER enhanced features large capacity electric trolley hoists offer high performance while handling heavier loads. Features include a fan cooled motor for preventive maintenance and a unique chain guide and pocket wheel that provides quiet and smooth guiding of chain.

CAPACITY

- 8 – 20 Ton

VOLTAGE

- 208-230/460-3-60

- Dual speed models are not reconnectable

COMPLIANCE

- UL 1340 – Most models shipped with UL listing. Contact Customer Service for listed models.

- ANSI/NFPA 70, “National Electrical Code”

- ANSI/ASME B30.16, “Safety Standard—Overhead Hoists (Underhung)”

- ANSI/ASME HST—1M, “Performance Standard for Electric Chain Hoists”

CLASSIFICATION

- ASME H4

- ISO M4

- FEM 2m or 1Am

BODY

- Rated IP55

- Die-cast aluminum

- Completely sealed body for for both indoor and outdoor applications, including harsh environments

- Low headroom

- Easy access external pins allow for quick change from hook to lug for trolley mount configurations on most models

GEARS

- Heat treated helical and spur gears are precision machined for long life

- Oil bath lubrication promotes a quiet, smooth, cool operation

LOAD CHAIN

- Ultra-strong high-performance and corrosion resistant nickel-plated

- Grade 80 DIN chain

- Made with unique technology to greatly increase resistance to fatigue and wear

OPERATION

- Pendant control

- Under-the-cover VFD standard for dual speed hoists. Speed ratio is 3:1 with adjustability up to 12:1

- Plug in pendant and power supply cords save time on set up and maintenance

HOOKS

- Forged carbon steel

- Open gradually without fracturing under excessive loads

- Bottom hook swivels 360 degrees

- Top and bottom hooks have heavy-duty hook latch

GREEN INITIATIVE

- Built smarter without the use of harmful materials.

- Environmentally friendly

- RoHS compliant

PUSH BUTTON PENDANT

- Rated IP65

- Standard control voltage is 110V

- Strain relief wire is molded to pendant cord for added support and dependability

- Single speed: 2-button (momentary contacts)

- Dual speed: 2-button (momentary contacts) with emergency On/Off (maintained contacts)

- E-stop is standard on all 2-button dual speed pendants

BRAKE

- “The Guardian”: Smart Brake Technology

- Revolutionary DC current motor brake with electrical failsafe design

- 10 year warranty

MOTOR

- Totally enclosed fan-cooled (TEFC)

- Motor fin, fan blade and fan cover design cools the motor and brake

OPERATING CONDITIONS

- Recommended for -4° to +104° F and humidity of 85% or less

OPTIONS

- Canvas or steel chain containers

- Longer lift or pendant lengths

- Other voltages