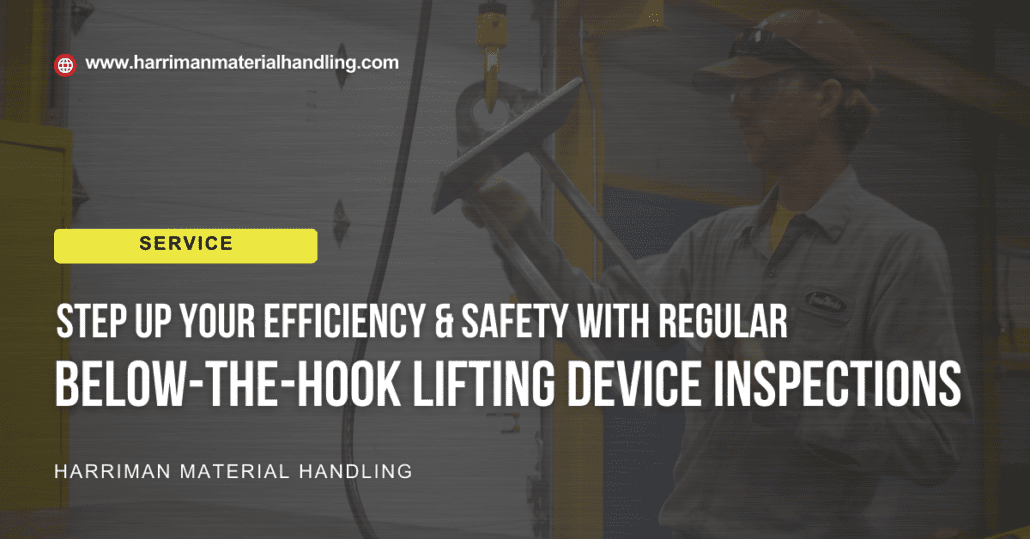

Why Below-the-Hook Lifting Device Inspections Matter

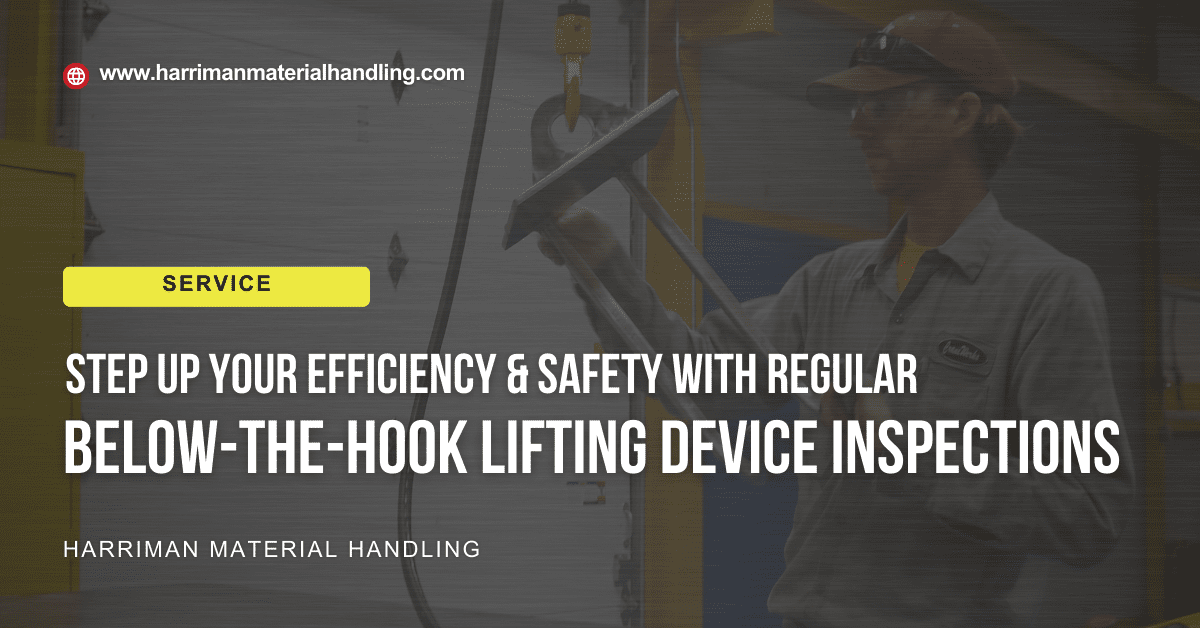

Maintaining compliance with OSHA standards is just the tip of the iceberg. A consistent inspection routine keeps plant operations running smoothly by lowering the risk of breakdowns, identifying small issues before they become big problems, and reducing costly downtime. It’s all about maintaining a reliable, productive, and safe work environment.

Below-the-hook lifting devices are specialized tools designed to attach to a crane or hoist hook, handling tasks like turning, gripping, or balancing loads that traditional hooks can’t manage. From shackle yokes to drum handlers and vacuum lifters, below-the-hook lifting devices are as diverse as they are crucial. But no crane job is truly complete until there’s a proactive maintenance plan in place for these unique rigging attachments—and that’s where Harriman Material Handling (HMH) comes in.

Compliance and Safety: Meeting OSHA Standards with HMH Inspections

HMH provides both frequent (monthly) and periodic (annual) inspections, following the OSHA 1910.179 and ANSI/ASME standards for overhead and gantry cranes. With these inspections, you’re not only ensuring compliance with safety regulations but also gaining an edge in operational reliability. Each inspection, whether it’s monthly or annual, goes beyond a checklist, focusing on elements like structural integrity, alignment, and functionality to prevent equipment failure.

Inspections Boost Your Bottom Line

When below-the-hook lifting devices are in top condition, they can improve efficiency across the board, enabling faster and more precise operations. Additionally, spotting wear-and-tear or alignment issues early on can prevent larger repairs, extending the life of your equipment and lowering overall maintenance costs. Keeping these devices working effectively means production isn’t just smoother—it’s smarter.

The HMH Advantage

With HMH’s expert inspection services, you can focus on what you do best: pushing efficiency and productivity to new heights. Leave the compliance and maintenance to us so you can keep your attention on the work that moves your business forward. HMH offers the experience and insight to keep your BTH devices running strong and ready to tackle your toughest projects.