Application

Customer: Major National Diesel Engine Manufacturer

Dealer: Harriman Material Handling

Below-hook Device Designer, Manufacturer, and Installer: CraneWerks, Inc.

Engine Manufacturer: Cummins, Inc.

Generator and Power Systems Manufacturer: Fridley Minnesota

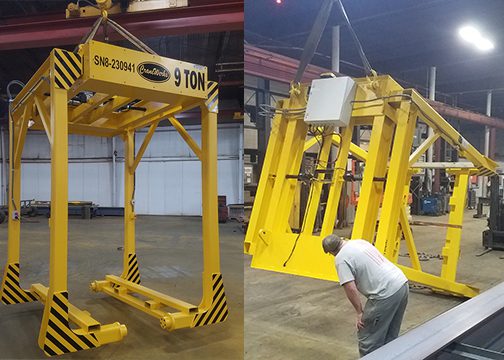

The customer was a Columbus, Indiana company that makes diesel engines for commercial vehicles. They needed a below-hook lifting device, a genset lifter, to pick up a fully assembled commercial diesel engine with 30-liter Fridley diesel generator.

Challenge

Our customer needed a lifting device to pick up their fully assembled 9 ton engine and generator. This fixture needed to be able to locate around a large engine and onto the supporting frame. There were limited locations that would allow the fixture to lift the engine assembly safely with no damage to the supporting frame. The fixture, a genset lifter, needed to be battery-powered, while still providing enough power to operate.

Solution

CraneWerks provided a custom grab-lifting device – a carefully engineered genset lifter solution that doesn’t damage the engine or its supporting frame. This fixture is large enough to locate around the engine while providing enough travel to safely close around the entire assembly and lift its nine tons. The genset lifter device includes a redundant locking mechanism that automatically provides a mechanical lock when in the locked position. An indicator light displays lights to the operator to inform when the fixture is locked and ready to lift. A battery-operated system provides abundant power to operate the fixture’s many moving parts, along with a remote to control operation.

Results

Customer received a custom, affordable genset lifter design to safely lift their engine assemblies, one that’s much more efficient and safer than previously-used equipment. Their new CraneWerks fixture perfectly balances the engine assembly while providing a convenient power source for mobile operation.

https://www.harrimanmaterialhandling.com/wp-content/uploads/2025/04/G-FORCE-FEAT-IMG.png

628

1200

Harriman Material Handling

/wp-content/uploads/2020/11/Tag-Line-Full-Color-300x155.png

Harriman Material Handling2025-04-18 17:38:132025-04-18 17:52:30G-Force® ViPlus

https://www.harrimanmaterialhandling.com/wp-content/uploads/2025/04/G-FORCE-FEAT-IMG.png

628

1200

Harriman Material Handling

/wp-content/uploads/2020/11/Tag-Line-Full-Color-300x155.png

Harriman Material Handling2025-04-18 17:38:132025-04-18 17:52:30G-Force® ViPlus